Contact Us

E-mail :

Dayi Mechanical and Electrical Engineering in Liangyuan Park, Shangqiu City, Henan Province

Negative pressure distillation

- Commodity name: Negative pressure distillation

- Product Description

-

Video detailed display of details

Product description

Waste oil distillation is a process that heats the oil to evaporate and then condense components with different boiling points. This separates impurities and recovers usable oil. Single or double distillation columns are often used for this separation, with the double-column method improving oil purity. Alkali or catalysts can be added to remove harmful substances and increase recovery efficiency. The process must properly handle waste gas and residues to prevent pollution. It plays an important role in resource recycling and environmental protection.Distillation plant models and specification

product model Specifications per batch capacity Containers Gross weight power RD-2200*6600 2200mm*6600mm 10T 2*40HQ 25T 25KW RD-2000*6600 2000mm*6600mm 15T 2*40HQ 35T 30kw RD-2600*8000 2600mm*8000mm 20T 1*40HQ&1*FR 37T 30kw RD-2600*8000 2600mm*8000mm 30T 1*40HQ&1*FR 38T 30kw product attributes

Place of Origin:

Shangqiu City, Henan Province, China

Brand: Runda Voltage: 380V 50HZ/60HZ (customized) Raw materials:

Waste engine oil, engine oil, heavy fuel, fuel oil

Heating methods: electricity, gas, wood, fuel oil Cooling method: water circulation system Warranty period: 1 year Temperature: 360 degrees - 460 degrees Negative pressure:

Atmospheric pressure:-0.07Mpa

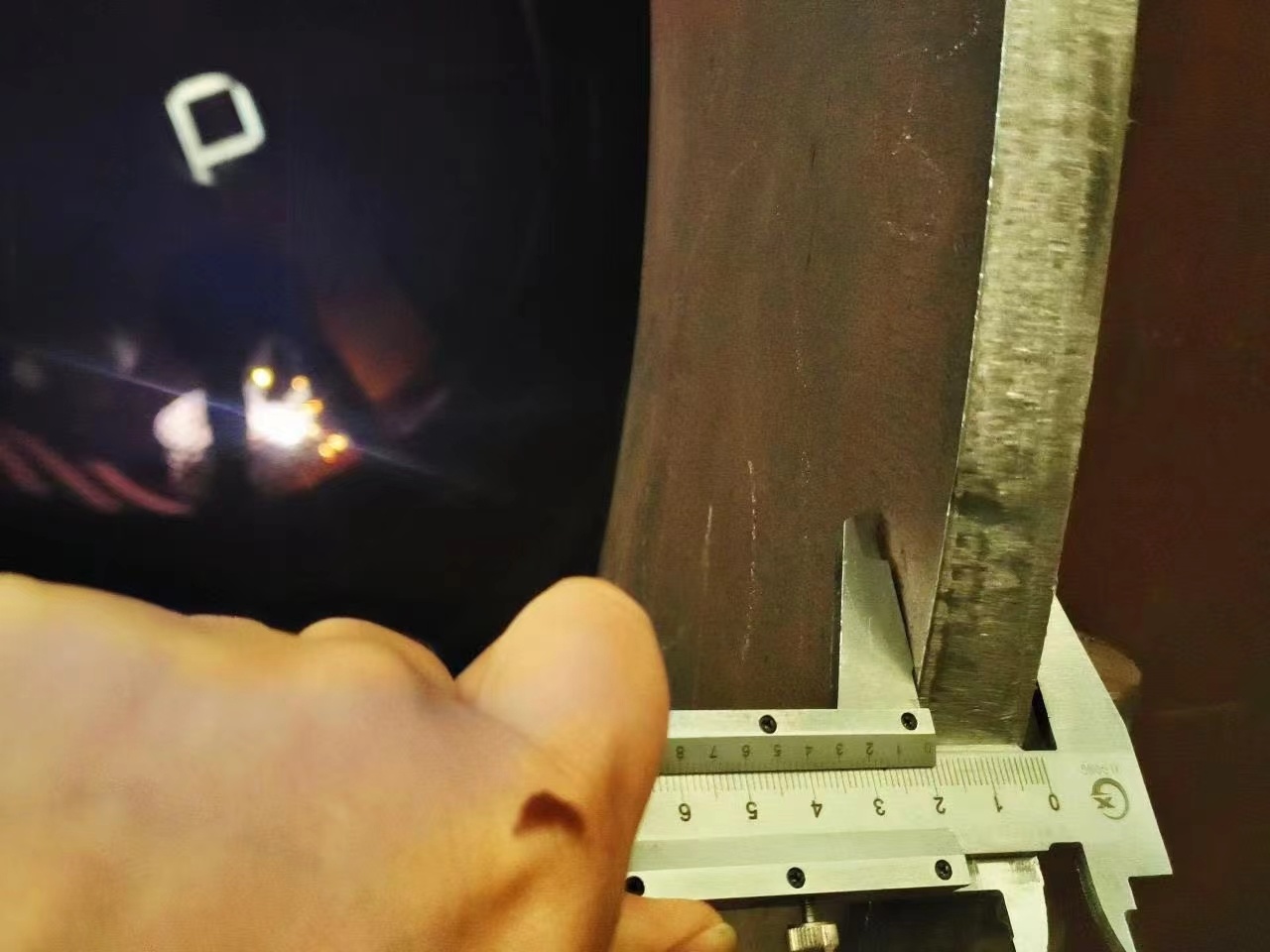

0.04MpaPictures of the scene

On site 15 ton distillation equipment in Kenya, Africaproduction workshop

Product shipment

service

1.Full year support for maintenance, 24-hour technical hotline 2.Conduct training for operation and maintenance personne 3.Develop a visual operation and maintenance manual 4.Regular preventive maintenance plan 5.Core component lifespan warning and update reminder

Keywords:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products