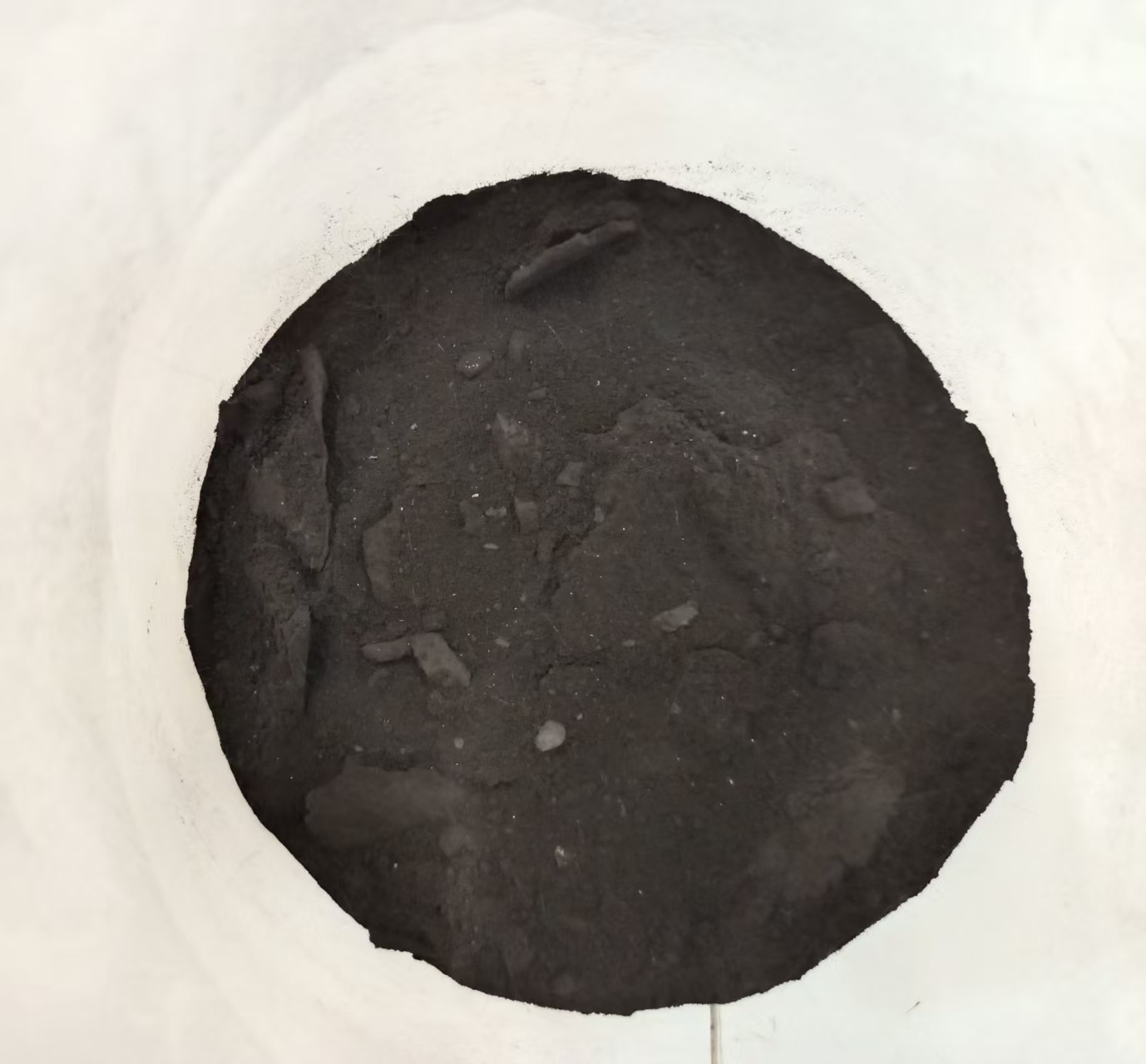

carbon black

Contact Us

E-mail :

Dayi Mechanical and Electrical Engineering in Liangyuan Park, Shangqiu City, Henan Province

Waste solar panel treatment plant

- Commodity name: Waste solar panel treatment plant

- Product Description

-

Video detailed display of details

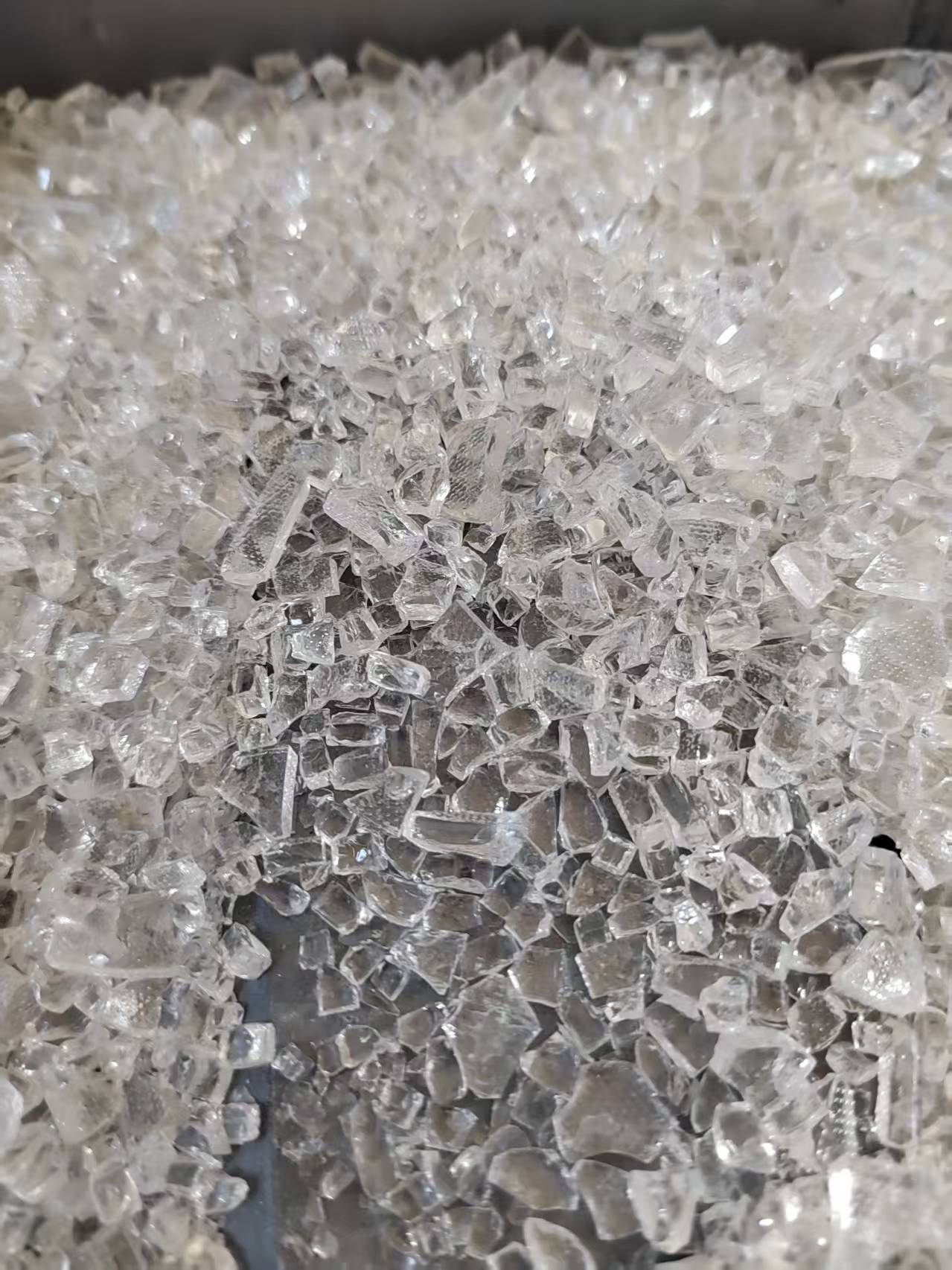

Final Product

In photovoltaic panel modules, glass (75%) is followed by polymer (7%), aluminum (9%), silicon (4%), copper (1%), and small amounts of silver, tin, lead, etc. Among them, metals such as glass, aluminum frames, silicon, copper, silver, tin, and plastic oil have significant recycling value. Waste photovoltaic panel resistors also have great recycling value.

Product Attributes

Place of Origin:

Shangqiu City, Henan Province, China

Brand: Runda capacity: customizable Warranty period: 1 year Raw materials:

Single glass panel and double glass of waste solar panel

Heating methods: electricity, gas, wood, fuel oil Cooling method: water circulation system Temperature: 0 degrees - 450 degrees recovery rate:

98%

Processing capacity: 40T-80T Number of workers: 10-15person floor area: 2000 square meters Process principle of processing equipment:

1.The pyrolysis process does not require fine pretreatment of the raw materials. After remove the aluminum frame of the waste solar panel, it can be directly put into the pyrolysis processor for treatment.

2.During the pyrolysis process, a amount of glass, silicon, and other substances will be separated from EVA adhesive (ethylene vinyl acetate copolymer). EVA adhesive is distilled to produce an oil vapor mixture, which is then condensed by a multi-stage separator and cooling system to recover fuel oil. Meanwhile, solid residues are retained in the pyrolysis furnace.

3.The waste gas and flue gas generated by pyrolysis are treated by an atomization dust removal device to ensure that pollutants are discharged in compliance with standards. Some of the low-carbon non condensable gases enter the combustible gas recovery system through a water seal device and can be used as fuel for the combustion and heating of the pyrolysis furnace.

4.After pyrolysis is completed, the solid materials in the furnace are cooled and discharged, and then subjected to physical and mechanical screening to separate metal and non-metal materials such as silicon, copper, silver, and glass.

Prolysis plant models and specification

product model Specifications per batch

capacityContainers Gross weight power RD-2600*6600 2600mm*6600mm 10T 2*40HQ 27T 24KW RD-2800*6600 2600mm*6601mm 12T 1*40HQ&1*FR 36T 25kw RD-2600*7700 2600mm*6602mm 12T 1*40HQ&1*FR 39T 25kw RD-2800*7700 2600mm*6603mm 15T 1*40HQ&1*FR 41T 27kw RD-2800*8000 2600mm*6604mm 15T 1*40HQ&1*FR 42T 27kw Customer Site

Equipment shipment

Service

1.Full year support for maintenance, 24-hour technical hotline 2.Conduct training for operation and maintenance personne 3.Develop a visual operation and maintenance manual 4.Regular preventive maintenance plan 5.Core component lifespan warning and update reminder

Keywords:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products