Contact Us

E-mail :

Dayi Mechanical and Electrical Engineering in Liangyuan Park, Shangqiu City, Henan Province

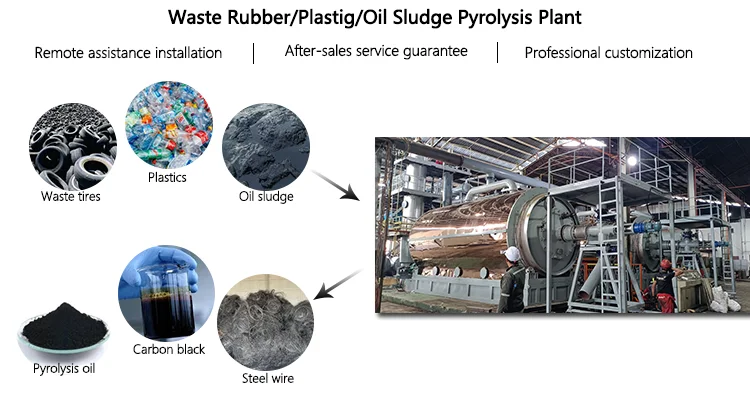

waste tyre pyrolysis plant

- Commodity name: waste tyre pyrolysis plant

- Product Description

-

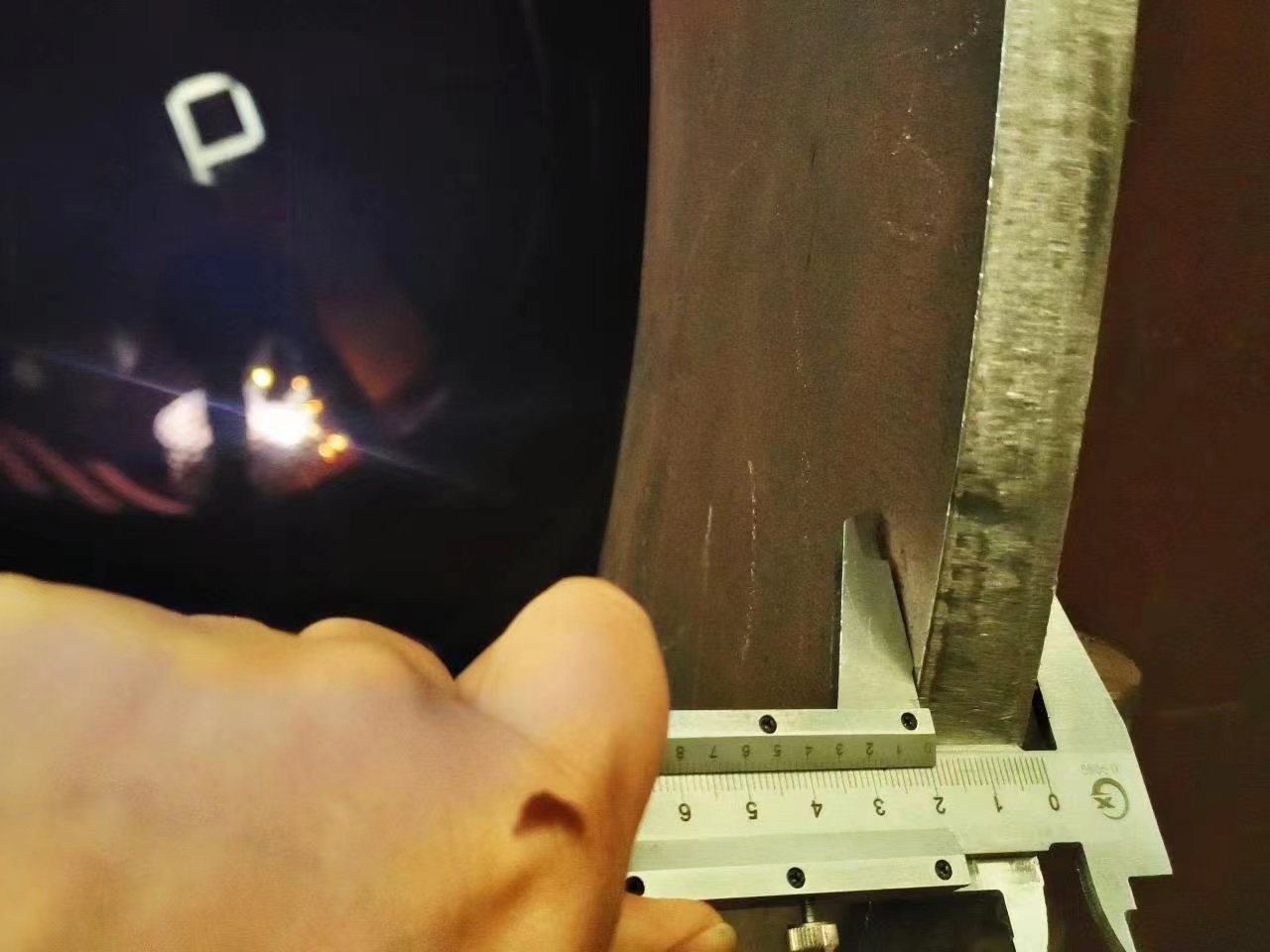

Video detailed display of details

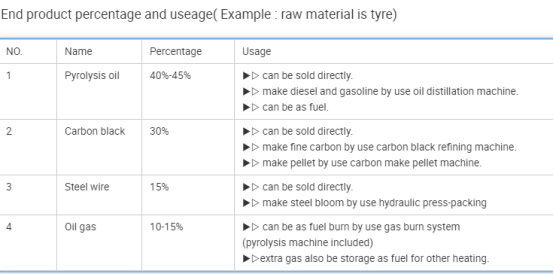

Products after oil sludge pyrolysis and their uses

The products of oil sludge pyrolysis are not only rich and diverse, but also have their own unique value and a wide range of applications. First, let's delve into the products of sludge pyrolysis.

In addition to producing fuel oil, sludge pyrolysis also produces a large amount of solid residue. After further treatment and processing, these residues can be converted into valuable building materials. For example, the carbonaceous component of the residue can be used to make activated carbon, and the siliceous component can be used to make building materials such as silica bricks. These building materials not only have good physical properties and chemical stability, but also have relatively low prices, and have broad market prospects.

In addition, the sludge pyrolysis residue can also be used for soil improvement. Because the residue contains a large amount of organic matter and trace elements, these substances have a good effect on soil improvement. By mixing the residue with the soil, the fertility and air permeability of the soil can be improved, and the growth and development of plants can be promoted. At the same time, this method can also reduce the use of chemical fertilizers and pesticides, and reduce the pollution of agricultural production to the environment.

In short, the products of sludge cracking have a wide range of applications and great commercial value. Through scientific processing and processing technology, we can transform these products into valuable resources and products, and realize the recycling and sustainable development of resources.

Prolysis plant models and specification

product model Specifications per batch

capacityContainers Gross weight power RD-2600*6600 2600mm*6600mm 10T 2*40HQ 27T 24KW RD-2800*6600 2600mm*6601mm 12T 1*40HQ&1*FR 36T 25kw RD-2600*7700 2600mm*6602mm 12T 1*40HQ&1*FR 39T 25kw RD-2800*7700 2600mm*6603mm 15T 1*40HQ&1*FR 41T 27kw RD-2800*8000 2600mm*6604mm 15T 1*40HQ&1*FR 42T 27kw Waste Tire pyrolysis

The process of waste tire pyrolysis involves the controlled thermal decomposition of tires to produce valuable by-products. This environmentally friendly technique converts what would otherwise be considered waste into useful resources, offering a sustainable solution to the growing problem of tire disposal.

During the pyrolysis process, tires are heated in a closed chamber under controlled conditions. As the temperature rises, the rubber components of the tires begin to break down, releasing gaseous hydrocarbons and solid carbon black. These hydrocarbons can then be condensed to produce oil, which can be further processed for use in various industrial applications.

The carbon black recovered from the process is also of high value, finding uses in products such as inks, coatings, and rubber reinforcements. Additionally, the steel wires and fibers present in the tires can be separated and recycled for further use.

Not only does waste tire pyrolysis reduce the burden on landfills and incineration facilities, but it also creates economic opportunities. The recovered oil and carbon black can be sold to generate revenue, while the recycling of steel and fibers can contribute to a circular economy.

As the world faces increasing challenges in waste management and resource scarcity, waste tire pyrolysis represents a promising solution. It offers a way to turn a seemingly intractable problem into a valuable resource, promoting environmental sustainability and economic growth.

Pictures of the scene

Production Workshop

On site installation of foreign equipment

Keywords:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products