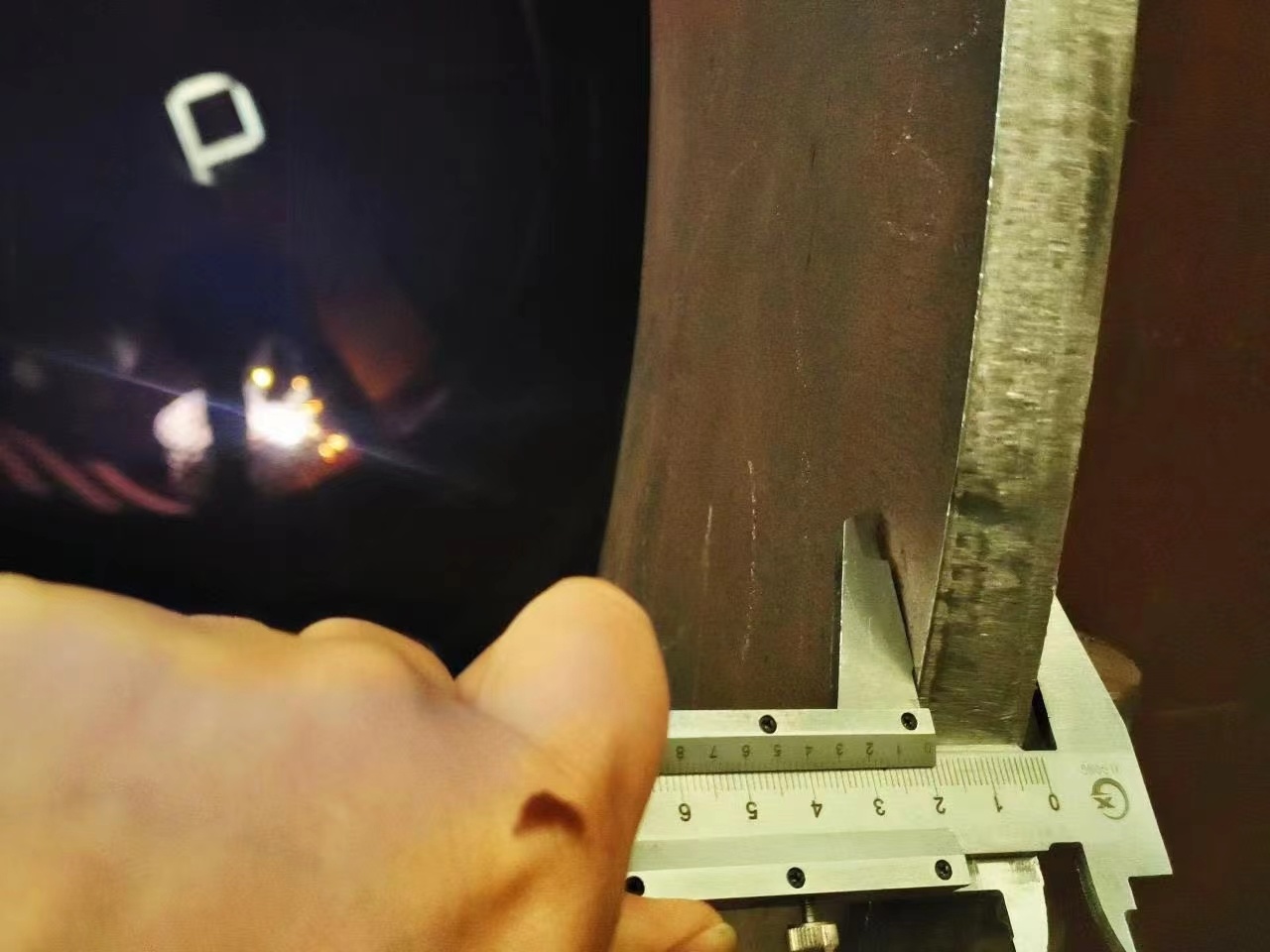

Mexican customer inspection

Contact Us

E-mail :

Dayi Mechanical and Electrical Engineering in Liangyuan Park, Shangqiu City, Henan Province

Plastic to Oil Machine | Advanced Pyrolysis Technology | CE/ISO Certified

- Commodity name: Plastic to Oil Machine | Advanced Pyrolysis Technology | CE/ISO Certified

- Product Description

-

Video detailed display of details

Plastic pyrolysis products and their applications

Plastic pyrolysis is an environmentally friendly technology that converts waste plastics into high-value products through high-temperature anaerobic decomposition. The main products include pyrolysis oil, pyrolysis gas, and solid residue.Plastic pyrolysis products yield proportion applications Pyrolysis oil 60-80% can be directly used as fuel in industrial kilns, or refined into diesel, gasoline, and can also extract chemical raw materials such as benzene and toluene; Pyrolysis gas 10-20% Containing methane, hydrogen, and other gases that can be burned to generate energy and used as raw materials for chemical synthesis; Solid residues 5-15% such as carbon black can be used in industries such as rubber and building materials. In addition, the pyrolysis products of different plastics vary. For example, PET can recycle terephthalic acid for the regeneration of polyester, while PVC requires the treatment of by-product HCl gas. This technology can achieve resource recycling and reduce carbon emissions, but it needs to optimize the process to address challenges such as the treatment of chlorinated plastics.

Prolysis plant models and specificationproduct model Specifications per batch

capacityContainers Gross weight power RD-2600*6600 2600mm*6600mm 10T 2*40HQ 27T 24KW RD-2800*6600 2600mm*6601mm 12T 1*40HQ&1*FR 36T 25kw RD-2600*7700 2600mm*6602mm 12T 1*40HQ&1*FR 39T 25kw RD-2800*7700 2600mm*6603mm 15T 1*40HQ&1*FR 41T 27kw RD-2800*8000 2600mm*6604mm 15T 1*40HQ&1*FR 42T 27kw Product description

Place of Origin: Shangqiu City, Henan Province, China Brand: Runda capacity: customizable Warranty period: 1 year Raw materials: Plastic (PP PE), rubber, waste tires, oil sludge Heating methods: electricity, gas, wood, fuel oil Cooling method: water circulation system Temperature: 0 degrees - 450 degrees Customer Visit

Runda Company has currently exported to more than 20 countries, and foreign customers visit the factory for inspections every dayProduction workshop

welcome to visit our refinery equipment production workshop. We specialize in the manufacturing of large pressure vessels and critical process equipment here. We have core processes such as large coil bending, automatic welding, and non-destructive testing, strictly following ASME and GB regulatory standards. Through full process quality control, we ensure that every factory equipment has safe, reliable, and continuously stable high-performance performanceService

1.Full year support for maintenance, 24-hour technical hotline 2.Conduct training for operation and maintenance personne 3.Develop a visual operation and maintenance manual 4.Regular preventive maintenance plan 5.Core component lifespan warning and update reminder

Keywords:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products